Need more details?

Get a quotation?

Request for a demo?

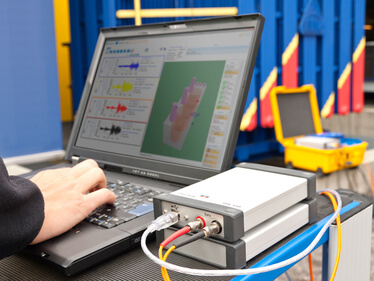

PDL 650

Acoustic partial discharge localization in power transformers

Locates insulation defects

The PDL 650 is an acoustic partial discharge (PD) localization system for pinpointing the location of insulation defects in power transformers. Even at an early stage, insulation defects produce measurable partial discharges, which emit electrical and acoustic signals at the same time. The PDL 650 measures the acoustic signals with multiple sensors installed across the surface of the transformer.

PDL 650 at a glance

Innovative defect localization

The PDL 650 software uses the time difference of incoming signals from all acoustic sensors to determine the location of an insulation defect in the transformer. The coordinates of the defect location are shown in a 3D model of the transformer. This information allows users to quickly act and take necessary maintenance actions to prevent failure.

“Using the PDL 650 for acoustic PD measurements, weak points or defects in power transformer insulation can be precisely located. Once located, remedial steps can be efficiently planned and timely executed.”

Key features

- Efficient because repairs and spare parts are predictable when failure location is known

- Easy creation of reports and records

- Safe due to galvanic separation of operator from high-voltage

- Convenient and handy through light weight, small size and battery operation

Applications

- Manufacturing process of transformers

- Final acceptance test at transformer manufacturers

- Yearly maintenance of transformers

- Localizing failures prior to necessary repairs

Download the latest software version for PDL 650 in our Customer Portal.

Solution for:

Documents

Get in touch

Need more details?

Get a quotation?

Request for a demo?

Contact us now

To ensure that you receive the highest quality products and enjoy full customer support, please acquire our products exclusively through our authorized sales channels as portrayed on this site.