Contact Resistance Measurement on Rotating Machines

Contact resistance measurements are performed to detect loose connections as well as oxidized or damaged contact surfaces on the pole connectors of rotating electrical machines. These defects generate hot spots, which can lead to disconnection of the poles. DC current and DC voltage are measured at the same time for each pole connector of the rotor.

These measurements are compared to one another and to previous measurements to calculate the contact resistance. Poles with higher resistance values indicate possible loose or damaged connections.

Expert recommends

CPC 100 + Primary Test Manager (PTM)

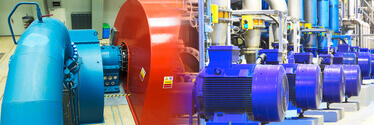

The patented CPC 100 multi-functional test system replaces several individual testing devices. This reduces the costs for training and transport, and cuts down testing time. Therefore, the CPC 100 is the ideal test set for performing a variety of off-line electrical tests on motors and generators, such as insulation resistance, polarization index and dc winding resistance measurements, among others. You can operate the CPC 100 via the integrated front panel, or by using the Primary Test ManagerTM (PTM) software on your laptop. The software also supports you during diagnostic testing, condition assessment and data management of your motors and generators.

Benefits of this solution

Ideal for field use

Precise measurements