Electromagnetic Imperfection Testing

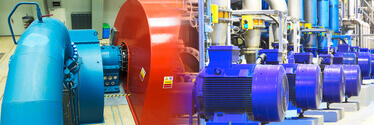

The electromagnetic imperfection test (also known as stray flux measurement, ELCID) is performed to detect stator core interlamination imperfections that can eventually cause overheating and damage to the stator core of motors and generators when in operation.

Stator core measurements are performed offline during bigger maintenance shutdowns. They should be performed on a regular basis to evaluate the insulation integrity between the stator core layers of a machine during factory acceptance testing and commissioning, as well as after the machine has been put into service. The test results are compared with previous test results to verify stator condition.

Expert recommends

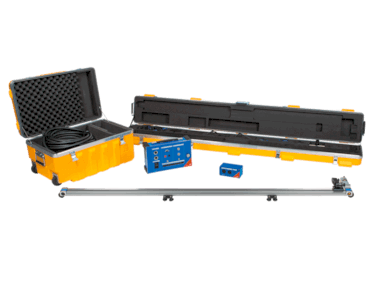

CPC 100 + Stator Core Measurement Upgrade Option

The Stator Core Measurement Upgrade Option is used for electromagnetic imperfection testing, also known as stray flux measurements. It reliably detects interlamination imperfections in the stator core of rotating electrical machines, including motors and all types of power generators. Used together with our CPC 100 multi-functional testing device, our complete solution provides you with a frequency-selective, highly-sensitive and efficient measurement approach. The measurement sensor automatically moves along a mounted rail, scanning the entire length of the stator core surface below. You can move the rail to scan other areas of the stator core. The solution’s intuitive software allows you to generate reports on site with a single mouse click.

Benefits of this solution

Time-Saving Solution

Complete Assessments