Instrument Transformer Testing

Instrument transformers (ITs) for metering purposes must have a high accuracy up to class 0.1 for accurate billing. Hence, it is essential to inspect and calibrate them at regular intervals.

ITs for protection purposes supply protection relays and must also function accurately at a multiple of the nominal current. A regular inspection should ensure that ITs, together with the connected relays, react quickly and correctly in the event of a fault and guarantee the highest possible security of supply.

The importance of IT tests is often underestimated. Risks such as confusing ITs for metering and protection or mixing up connections can be reduced significantly by testing before initial use. At the same time, damages to the

interior of an instrument transformer, caused for example during shipping, can be recognized easily. Also changes in an IT, caused for example by aging insulation, can be identified at an early stage.

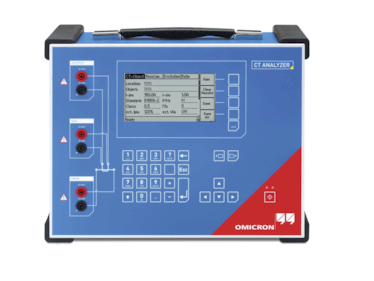

Our test systems provide high-precision, automatic testing and assessment of CTs to IEC 60044-1, IEC 60044-6, IEC 61869-2, IEEE C57.13 and IEEE C57.13.6 standards; VTs to IEC 60044-2, IEC 60044-5, IEC 61869-3, IEC 61869-5, IEEE C57.13 and IEEE C57.13.6 standards; combined transformers to IEC 60044-3 and of IEC 61850 standards.