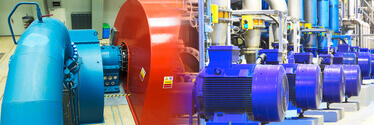

Pole Drop Testing on Rotating Machines

Mechanical stress in rotor windings cause inter turn faults (short circuits), which can lead to magnetic imbalance in generators and motors. This causes higher shaft vibrations, resulting in stress and damage to the bearings. Similar to sweep frequency response analysis (SFRA), the pole drop test is performed on single pole windings when the machine is in a standstill condition.

An AC current is injected into the slip rings to energize the pole windings. By measuring the voltage drop of every pole between the pole winding connectors, the impedance can be determined. A comparison of the measurement results of each pole or with previous measurements identifies possible inter turn faults in the pole winding.

Expert recommends

CPC 100 + Primary Test Manager (PTM)

The patented CPC 100 multi-functional test system replaces several individual testing devices. This reduces the costs for training and transport, and cuts down testing time. Therefore, the CPC 100 is the ideal test set for performing a variety of off-line electrical tests on motors and generators, such as insulation resistance, polarization index and dc winding resistance measurements, among others. You can operate the CPC 100 via the integrated front panel, or by using the Primary Test ManagerTM (PTM) software on your laptop. The software also supports you during diagnostic testing, condition assessment and data management of your motors and generators.

Benefits of this solution

Ideal for field use

Precise measurements

Saves time

Get in touch

Need more details?

Get a quotation?

Request for a demo?

Contact us now