Advanced Protection Testing

Protection relays supervise the correct functioning of high voltage (HV) and medium voltage (MV) power grids and connected assets, to support a continuous power supply. If installed and maintained properly, they allow for fast, reliable and selective fault elimination, while simultaneously guaranteeing a maximum of personnel and asset safety.

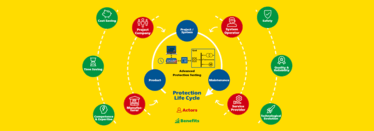

In order to ensure their correct operation, the devices have to be tested regularly by various actors during all stages of their life cycle. This is very time-consuming if conventional testing methods are used:

- Product stage: precision and type testing by manufacturers,

- Project stage: complete protection system testing during commissioning by a project company for example,

- Maintenance stage: regular or incident driven testing by system operators or service providers.

Advanced Protection Testing approaches such as organized, standardized or even automated parameter-based and system-based testing allow for a maximum in safety, quality, and reliability. At the same time, they reduce testing time as well as outages substantially. Of course, this directly impacts related costs. In addition, such an approach allows to maintain and transfer competencies and expertise among personnel as well as drive the technological evolution of protection systems.

![]()

Enormous time savings

Standardized test routines, protection testing libraries, and semi or fully automated testing significantly shorten the testing time, which leads to enormous savings over the device’s life cycle. Customers report that, with automated testing, they were able to reduce their previous effort to around one fifth of the time necessary for traditional manual testing. With the extra time at hand, many additional benefits can be leveraged.

![]()

Substantial cost savings

Testing time needed is directly related to costs. Labor and traveling costs are significantly reduced as automated testing and documentation takes far less time, while achieving the same or an even higher testing quality. Additionally, system outages and related costs are reduced while availability increases.

Customer studies have shown that a full return of investment (ROI) of a powerful and efficient automated relay test set is generally reached after only six months.

"Customers reduced their previous effort to around one fifth of the time."

![]()

Higher quality and reliability

Pre-prepared test routines, which can be standardized and executed semi or fully automatically, inevitably lead to a higher test quality and increased reliability of the protection system. Additional time invested into adding system-based testing to the parameter-based approach, is the most efficient way to detect hidden errors in settings, logic, and the design of protection systems. This pays off, as it not only results in reduced time and costs associated with finding and correcting faults, but also in a higher overall system reliability, reduced damage to assets, and increased personnel safety.

![]()

Increased safety

If some of the reduced testing time is invested in the careful preparation of upcoming test activities, not only can efficiency be further increased, but so can safety. Clarifying connection drawings, safety instructions, and warnings, relevant to the test engineers, can be integrated into automated test routines, to ensure even smoother testing and increased personnel safety on site.

"Return on investment of a powerful and efficient automated relay test set

is generally reached after only six months."

![]()

Technological evolution

With the arrival of digital relays and a digital IEC 61850-based communication between control systems, protection relays and, in part, the primary equipment, the technological evolution in the power industry is currently progressing rapidly.

Advanced Protection Testing solutions allow companies to deploy and benefit from the advantages of modern digital protection systems. These solutions provide the necessary tools to integrate GOOSE and Sampled Values configuration modules into automated test routines which cover all kinds of repetitive tasks. This enables protection engineers to simplify the overall testing task in an IEC 61850 environment and save valuable time to fully focus on the interaction between protection functions and the electrical power grid.

![]()

Facilitated transfer of competencies and expertise

Protection experts are becoming increasingly difficult to find. Therefore, the transfer of knowledge from senior protection test engineers to new colleagues is an important challenge for many companies.

Organized and standardized test routines, which clearly show every step of how to test a specific protection function, are an excellent tool to document the protection testing principles used in the company and transfer them to new team members. By executing these routines step-by-step, instead of fully automated, experts have all the time they need to add explanations during internal training or handovers to customers’ maintenance engineers.

![]()

Switching from manual and traditional testing approaches to Advanced Protection Testing methods is one of the rare cases where major advantages are not matched by relevant disadvantages. Of course, initial training is required, but thereafter, Advanced Protection Testing generates substantial long-term benefits at all levels. From saving time and reducing costs, to increasing quality, reliability, and safety, to fostering the transfer of expertise and knowledge as well as technological development.