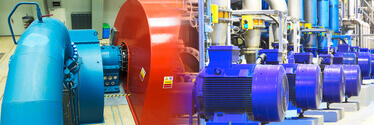

Offline Testing on Rotating Electrical Machines

Rotating electrical machines are critical for power generation and running critical processes in industrial applications. However, performance and reliability can be compromised over time due to the thermal, electrical, ambient and mechanical stresses motors and generators are continuously subjected to when in operation.

We have identified a set of essential off-line electrical diagnostic methods that will help you to perform complete on-site condition assessments of your motors and generators.

Literature

Solutions

Products for Offline Testing on Rotating Electrical Machines

Videos

Powerful 15kV test solution for rotating machines – CPC 100 + CP TD15 + CP CR600

Partial discharge testing on rotating electrical machines

Get in touch

Need more details?

Get a quotation?

Request for a demo?

Contact us now